Discover Top-Quality Engines for Africa at Our Dependable Automobile Components Store

Discover Top-Quality Engines for Africa at Our Dependable Automobile Components Store

Blog Article

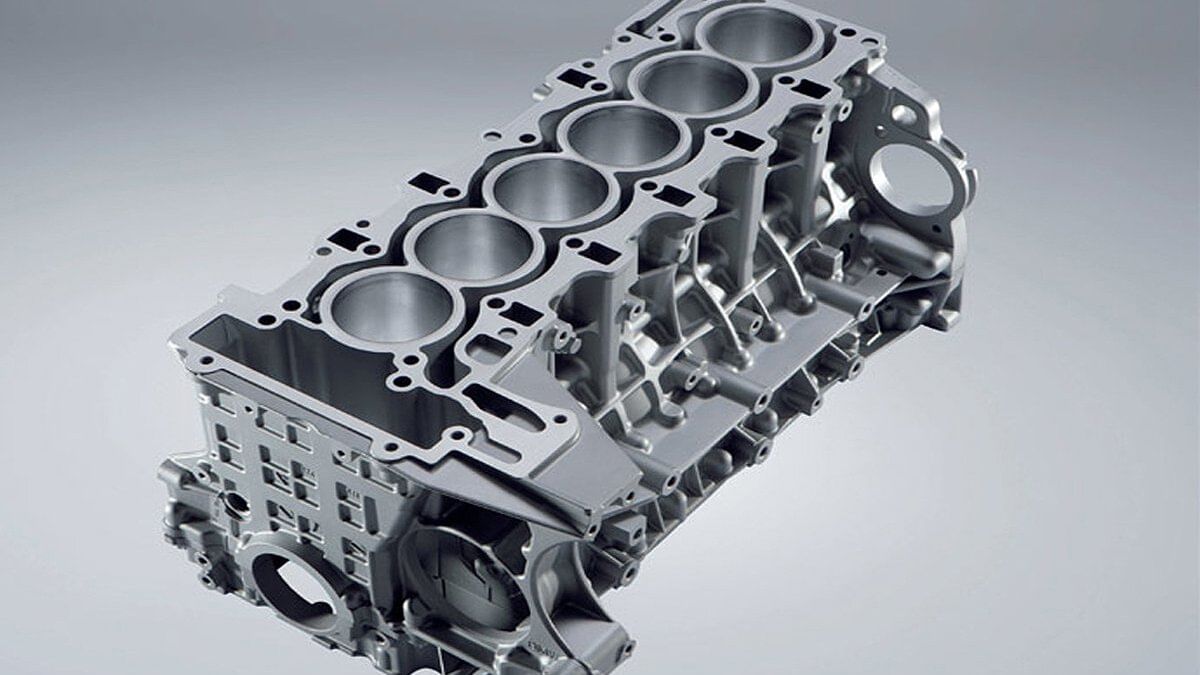

The Mission for Ultimate Driving Power: Checking Out the Peak of Engine Efficiency and Technological Developments in the Automotive Sector

In the world of auto design, the pursuit of optimum driving power has actually been an unrelenting pursuit that has unravelled with the evolution of engine style and the integration of advanced modern technologies. From the thorough craftsmanship of combustion engines to the rapid improvements in electrical propulsion systems, the automotive sector stands at the cusp of a brand-new era defined by unprecedented performance abilities. As designers and scientists dig deeper right into the worlds of computational fluid characteristics and discover cutting-edge gas technologies, the horizon of opportunities broadens greatly. Keep tuned as we unravel the intricate tapestry of technical breakthroughs that are shaping the future of auto power and performance.

Advancement of Engine Design

Moreover, the combination of turbocharging and supercharging modern technologies has transformed engine style by increasing power without significantly boosting engine size. These forced induction systems compress the intake air, permitting even more gas to be ignited, therefore creating greater power outcome from a smaller sized engine. This advancement has actually been specifically vital in boosting the efficiency of smaller sized variation engines while keeping gas effectiveness requirements.

Performance-Enhancing Gas Technologies

The implementation of innovative fuel modern technologies has substantially added to boosting engine performance in modern-day lorries. From standard fuel and diesel to cutting-edge biofuels, synthetic fuels, and hydrogen, the automobile market is witnessing a transformation in fuel alternatives. Biofuels, acquired from eco-friendly resources like sugarcane, corn, or algae, offer decreased discharges and boosted engine effectiveness. Artificial fuels, produced through chemical processes, offer high octane rankings, boosting power result. Hydrogen gas cells, although still in the very early stages of adoption, reveal great guarantee as a result of their zero-emission nature and potential for high performance. Additionally, gas ingredients and cleaning agents are being formulated to clean engine components, optimize combustion, and minimize rubbing, therefore increasing general lorry efficiency. With ongoing research study and advancement, the quest for the utmost driving power continues, as designers strive to open the full capacity of performance-enhancing fuel modern technologies in the auto sector.

Advancements in Electric Propulsion

Considerable strides in electrical propulsion innovation have revolutionized the automotive industry, paving the way for a new era of lasting and effective transport. Electric cars (EVs) are acquiring appeal due to their ecological benefits and advancements in battery innovation, making it possible for longer driving ranges and much shorter charging times. Producers are spending greatly in r & d to enhance the efficiency of electrical propulsion systems, concentrating on increasing power output, enhancing energy effectiveness, and minimizing general weight.

One noteworthy article source breakthrough in electrical propulsion is the advancement of sophisticated electric motors that provide greater torque and power density, resulting in improved acceleration and total driving efficiency. In addition, regenerative stopping systems have been improved to save and capture energy throughout deceleration, more boosting the efficiency of EVs.

Additionally, the assimilation of clever innovations, such as expert system and predictive analytics, is optimizing the monitoring of electrical propulsion systems, making certain ideal efficiency under numerous driving problems. These advancements in electrical propulsion are reshaping the automotive landscape, driving the sector towards a much more sustainable and amazed future.

Effect of Computational Fluid Dynamics

With improvements in electric propulsion pressing the boundaries of automobile technology, the assimilation of Computational Fluid Dynamics is playing a crucial function in enhancing wind resistant performance and improving overall performance in lorry style. Computational Liquid Dynamics (CFD) includes the usage of computer simulations to analyze the flow of air around a car, enabling engineers to anticipate just how design changes will certainly affect the rules of aerodynamics without the demand for pricey physical models. By properly modeling airflow patterns, CFD permits the refinement of car forms to lower drag, improve cooling, and boost stability.

CFD enables designers to enhance airflow around components such as radiators, engine bays, and wheel wells, adding to enhanced performance and overall driving experience. In verdict, the integration of Computational Liquid Characteristics represents a considerable step onward in the pursuit for ultimate driving power and efficiency in the automobile sector.

Future Fads in Engine Technology

In the vibrant landscape of automotive design, advanced developments are shaping the future trajectory of engine advancement. The future of engine design is noted by a strong focus on sustainability, efficiency, and effectiveness. Makers are increasingly focusing on creating engines that not only supply high power outcomes but also prioritize environmental duty by reducing emissions and enhancing fuel performance.

One prominent pattern in engine advancement is the increase of electrification. Hybrid and electric powertrains are obtaining traction as sensible choices to conventional combustion engines. These technologies offer the possibility for significant reductions in carbon discharges and raised power efficiency, try these out lining up with international efforts to battle climate change.

In addition, advancements in products science and manufacturing methods are enabling the production of lighter and a lot more durable engine parts. This change in the direction of lightweight products such as carbon fiber and aluminum alloys contributes to boosted efficiency and gas economic climate.

Final Thought

In verdict, the pursuit of ultimate driving power in the automobile sector remains to drive developments in engine style, gas technologies, electric propulsion, and computational liquid characteristics. The development of these technologies is shaping the future of engine advancement, leading the way for a lot more powerful and effective lorries (engines for africa). As the industry remains to press the borders of great site what is feasible, we can expect to see also extra cutting-edge growths in the pursuit for peak efficiency

One of the vital landmarks in engine design development is the shift from standard carbureted engines to contemporary fuel-injected systems. By precisely metering the gas shipment to each cylinder, fuel-injected engines maximize combustion, resulting in far better efficiency and minimized ecological effect.

Furthermore, the combination of turbocharging and turbo charging technologies has transformed engine style by improving power without considerably enhancing engine dimension (engines for africa).The application of innovative gas technologies has considerably added to improving engine efficiency in modern lorries. In addition, fuel additives and cleaning agents are being created to clean engine elements, maximize combustion, and minimize rubbing, therefore increasing total automobile efficiency

Report this page